Food HACCP: how to obtain certification for food safety

Food safety is an extremely topical issue, perhaps even more than in the past: the collective consciousness seems to be increasingly directed towards greater control of what is produced and consumed every day. This happens both on the side of producers and consumers. In addition, the changed health scenario brought by the Covid19 crisis has accelerated this process of seeking security. Therefore, the current context has rewarded all those protocols, such as food HACCP, which have been introduced in recent years to guarantee the healthiness of food and to protect consumers. The latter have proved to be increasingly attentive to the dynamics of production and distribution in the food sector, both for safety reasons and for various pathologies.

But what specifically is the food HACCP we hear so much about? What are the controls to which the products must be subjected to obtain this certification and what are the advantages of being able to communicate it to your customers?

Let’s find out in the next paragraphs by deepening the topic step by step.

HACCP food certification and food safety

Let’s start by explaining what food HACCP is, why this certification is so important and why, anyone who approaches the food world as a producer, distributor or even a simple collaborator in the food & beverage sector, must be aware of it. In fact, the issue of food safety, especially at the level of fundamental hygiene rules, must be known by all the actors involved in the supply chain. Beyond this general premise, the knowledge of HACCP, and above all its implementation, varies in degree according to the responsibilities of each one. For example, the knowledge – and application – of food HACCP regulations are highest in those production levels where food and beverages are handled, less at the transport level.

Therefore, anyone who has to work in the food sector must obtain this certification, which attests the knowledge of the basic rules applied to hygiene and safety of food (and beverages) at every level. This includes microbiology, conservation and maintenance rules up to the sanitation and sanitization of the instruments used. This certification, or food HACCP, can only be achieved by attending a special course.

But what does HACCP mean? The term is nothing more than the acronym for Hazard Analysis Critical Control Point, or Risk Analysis and Control of Critical Points. In other words, food producers, handlers and distributors need to be aware of the risks faced by food and how it is processed, stored and distributed. This allows you to implement all those safety and health hygiene procedures aimed at maintaining healthiness.

This is not just common sense, but it’s required by law from Legislative Decree 193/07, according to which a hygienic self-control activity is provided in all public establishments and food industries.

HACCP food checks: what to expect

What are the controls to which food is subjected in terms of food HACCP? What should those who work in the sector expect? First of all, it is a certification that must be possessed by all those who work in the food sector, but also those who are in direct contact with customers and provide food and drinks. This category includes: restaurateurs, bars, pastry shops, pizzerias, cafeterias, pubs, catering, bathing establishments and even wholesalers who take care of supplying them and act as intermediaries between production companies and the customer in a b2b perspective.

All these actors in the supply chain must have a self-control manual. In the manual, all the information necessary to regulate and keep an eye on every phase of the production or distribution and sale of food must be reported. There is also a part dedicated to defining the roles, as well as the responsibilities of each person and a part relating to information on raw materials, processing sites, tools and machinery used. In addition, there is even the part relating to staff training in food safety.

This document, which cannot therefore be standardized, is tailor-made for each company and must always remain up-to-date and available to the supervisory authorities.

HACCP food risk analysis: what it is

Food HACCP provides for multi-level control measures, hygiene and food safety standards to which reference must always be made. It is therefore essential that anyone involved in producing and distributing food or beverages knows well what the risks are related to various foods. Think of the various microbiological risks faced by meat or egg producers, but also about the responsibility of those involved in food processing and packaging and label preparation.

In this case it is essential to trace, every single ingredient manipulated or where they are processed and packaged because a single ingredient, even if in tiny quantities, could be lethal for those who are allergic. This is why it is mandatory to report on the label all the ingredients and possible allergens contained in the products, but also to underline whether these have been processed in factories where risky foods such as wheat, eggs or dried fruit are processed.

In any case, within the food HACCP, there are precise indications regarding the risk assessment and the activities that must be implemented. In particular, you must:

- identify the risks related to the various processes to which food is subjected (for the reason mentioned above)

- identify the Critical Control Points (CCP) and those phases where it is possible to intervene to prevent, eliminate or limit the risk

- define risk acceptability limits within CCPs and related health monitoring procedures

- prepare solutions to the problems that arise

- define the verification procedures to monitor the effectiveness and correct functioning of the solutions adopted

- it is necessary to prepare the documentation relating to the company and the HACCP plan.

How to comply with HACCP and food hygiene regulations

Trackyfood, which has always been very attentive to the issue of food safety and traceability, also in view of the HACCP protocol, has thought of an innovative data storage system relating to food traceability, which works in a simple and efficient way.

All the process registration data required by the HACCP manual can be entered into the Trackyfood digital platform in a simple way, historicized and always available to be viewed and printed. Temperature recording, checklist recording and many more go digital. Paper is eliminated, improving data security and data control.

At the same time it is a software that performs an integrated service that allows you to use the tool of the food chain certified with blockchain to apply it to your supply chain, at any time, and thus obtain many guarantees related to the path taken by the product and its characteristics.

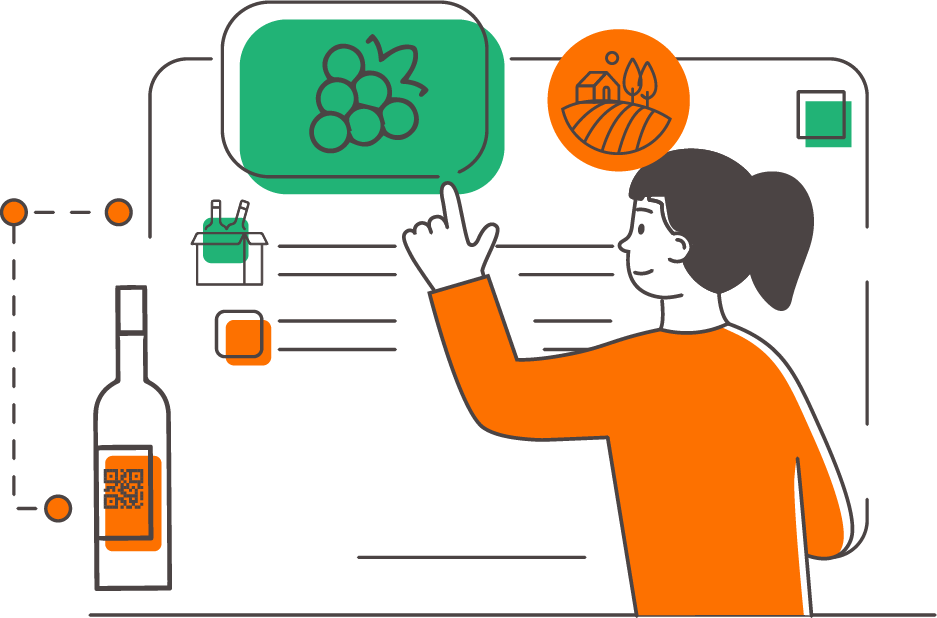

Trackyfood allows you to create an interactive label, protected by a key that makes it recognizable and unique, containing all the information related to the product and making it part of a controlled supply chain traced in all its parts. A product traceability key and a serialization of the tags is then generated by creating the QR Code. Finally, the blockchain-certified food supply chain system ensures that all data is stored and kept safe thanks to the block system. A safe and easy system that allows producers to communicate every single useful information regarding the issue of food safety, recording all the useful data in a special software. In this way, it is possible to comply with the rules expressed by the HACCP protocol and to provide them, when necessary, to the control bodies.

More news

Read the news we have selected for you. Lots of curiosities and information on the world of food.

The 5 Myths About Food Traceability

Food traceability has become an essential component of the mod..